Flow around three cylinder in equilaterial triangular arrangements

| this benchmark is based on [chen-2020]. |

1. Presentation of the test case

1.1. Presentation

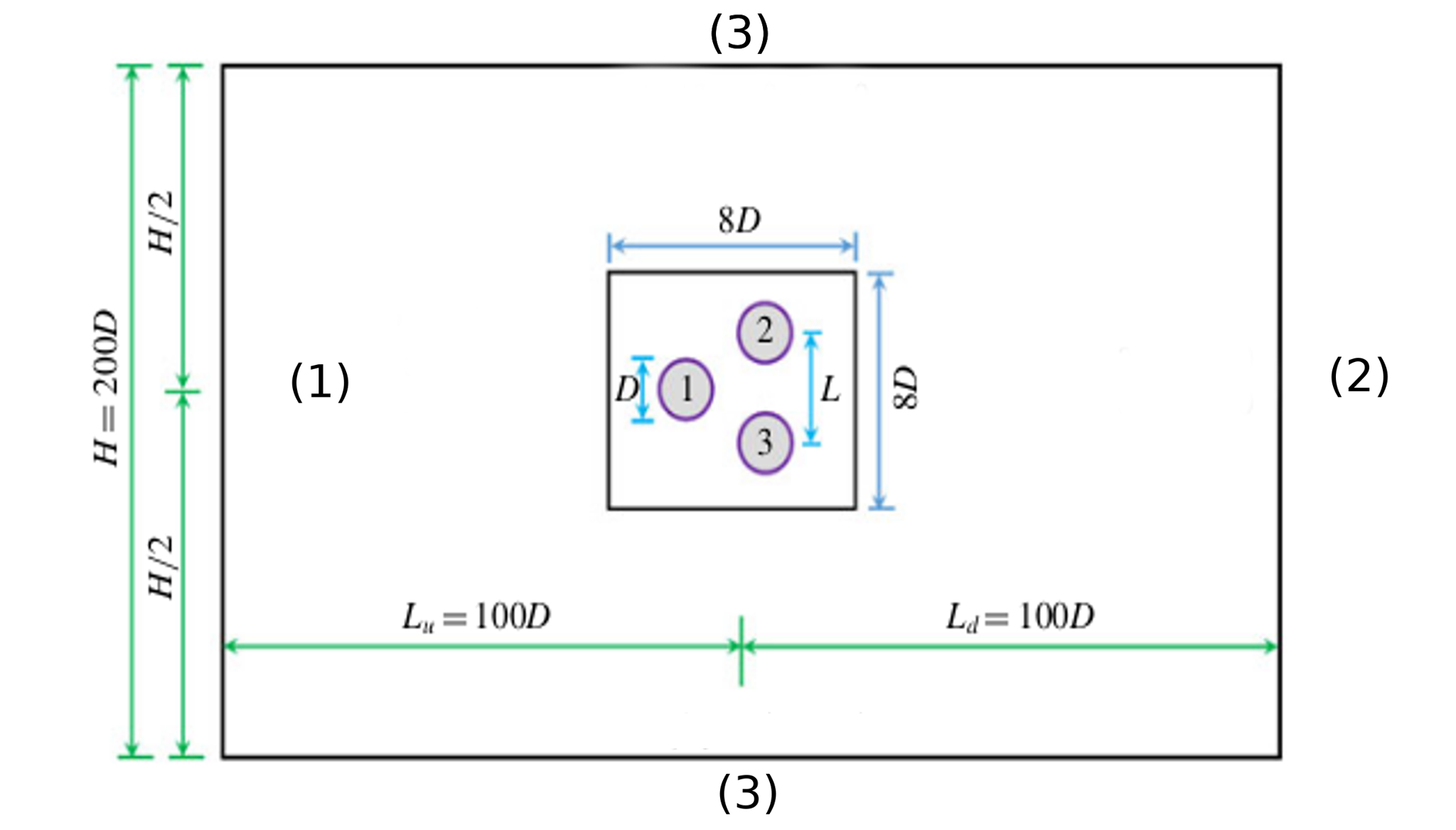

This study is based on the flow of a fluid in front of 3 circular and identical cylinders. The cylinders are arranged in an equilateral rectangle, one of the cylinders is placed upstream and the other two side by side downstream.

In this test case, we are particularly interested in the effect of the spacing ratio L/D and the number of Reynolds Re on the flow, where L is the center-to-center spacing of the cylinder and D is the cylinder diameter.

The numerical results obtained in this study, will be compared with those found in the literature, for different gaps \(L/D \in [1,6\)] and a Reynolds number \(Re \in [50,300\)].

1.2. Geometry setting

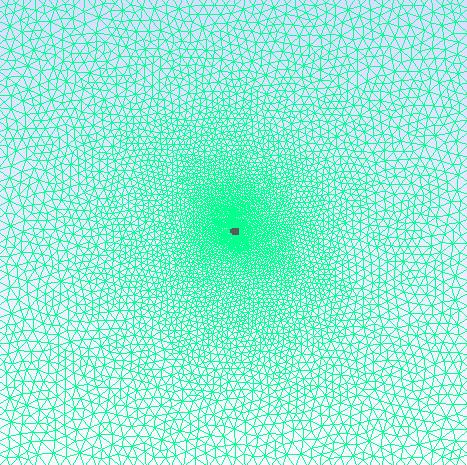

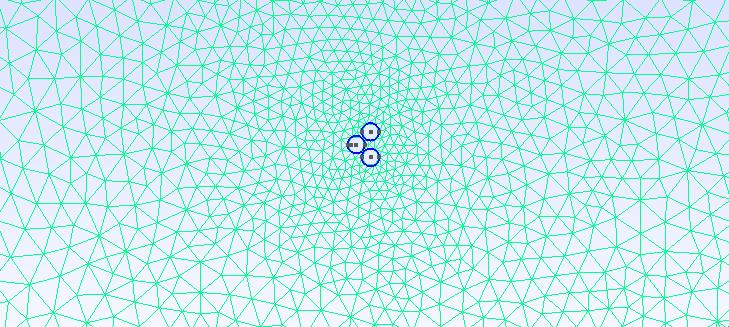

The arrangement of the cylinders in the calculation area \(\Omega\) is shown in the figure below :

We provide here the basic geometry used in Gmsh to describe \(\Omega\).

//GMSH

D=1.5;

L_sur_D=1.1;

L=D*L_sur_D;

H=200*D;

h=8;

Ld=100*D;

Lu=-100*D;

//caree

Point(1) = {0, 0, 0,h};

Point(2) = {Ld,H/2,0,h};

Point(3) = {Ld,-H/2,0,h};

Point(4) = {Lu,H/2,0,h};

Point(9) = {Lu,-H/2,0,h};

//+

Line(1) = {2, 3};

//+

Line(2) = {3, 9};

//+

Line(3) = {9, 4};

//+

Line(4) = {4, 2};

//+

Point(23) = {-L, 0, 0, h};//centre 1

//+

Point(17) = {L, L_sur_D, 0, h};//centre 2

//+

Point(18) = {L, -L_sur_D, 0, h}; //centre 3

//+

Point(24) = {L+D/2, L_sur_D, 0, h};

//+

Point(25) = {L-D/2, L_sur_D, 0, h};

//+

Point(26) = {L-D/2, -L_sur_D, 0, h};

//+

Point(27) = {L+D/2, -L_sur_D, 0, h};

//+

Point(28) = {-L-D/2, 0, 0, h};

//+

Point(29) = {-L+D/2, 0, 0, h};

//+

Circle(9) = {24, 17, 25};

//+

Circle(10) = {25, 17, 24};

//+

Circle(11) = {26, 18, 27};

//+

Circle(12) = {27, 18, 26};

//+

Circle(14) = {29, 23, 28};

//+

Circle(15) = {28, 23, 29};

//+

//surface

//+

Line Loop(1) = {9, 10};

//+

Line Loop(2) = {12, 11};

//+

Line Loop(3) = {14, 15};

//+

Line Loop(4) = {1, 2, 3, 4};

//+

Plane Surface(1) = {1, 2, 3, 4};

//+

Physical Line("inlet") = {3};

//+

Physical Line("outlet") = {1};

//+

Physical Line("wall1") = {4};

//+

Physical Line("wall2") = {2};

//+

Physical Surface("omega") = {1};The Data provided on the whole \(\Omega\) domain allows us to have conditions at the specified limits, the table below summarize these data.

| Notation | Description | Value | Unit |

|---|---|---|---|

\(D\) |

cylinder diameter |

- |

\(m\) |

\(L\) |

the center-to-center spacing of the cylinder |

- |

\(m\) |

\(H\) |

side of the domain |

200D |

\(m\) |

\(U\) |

Inlet velocity |

\(\frac{Re}{D}\) |

\(m/s\) |

1.3. Physical setting

The Physical parameters are:

| Notation | Description | Value | Unit |

|---|---|---|---|

\(\rho\) |

Density |

1 |

\(Kg/m^3\) |

\(\mu\) |

Dynamic viscosity |

1 |

\(Pa.s\) |

1.4. Boundary conditions

In this study 3 boundary conditions are imposed: Inlet condition, Outlet condition and the Wall condition.

-

Inlet condition

On boundary (1) a Dirichlet-type condition is imposed and a Poiseuille profile is placed as an entry condition, it’s defined by:

"inlet":

{

"expr":"{Re/D,0}:Re:D"

}-

Wall conditions

On the limits (3), i.e. on the upper and lower wall we have :

"wall1":

{

"expr":"0"

},

"wall2":

{

"expr":"0"

}-

Outlet condition

On boundary (2) (i.e the exit boundary condition) a Neumann-type condition is imposed

"Neumann_scalar":

{

"outlet":

{

"expr":"0"

}

}2. Configuration files

2.1. cfg file

directory=resulats/cylinders/P1

[case]

discretization= P2P1G1

dimension=2

[fluid]

filename=$cfgdir/cylinders.json

mesh.filename=$cfgdir/cylinders.geo

gmsh.hsize=8

solver= Newton #Oseen #Newton #Picard,Newton

linearsystem-cst-update=false

jacobian-linear-update=false

snes-monitor=true

pc-type= gams #gasm,lu

snes-rtol=1e-102.2. json file

Here the full json configuration file

{

"Name": "three circular cylinders in equilateral-triangular arrangements",

"ShortName":"flow past",

"Models":

{

"equations": "Navier-Stokes"

},

"Materials":

{

"omega":

{

"rho":"1",

"mu":"1"

}

},

"Parametres":

{

"Re":"100",

"D":"1.5"

},

"BoundaryConditions":

{

"velocity":

{

"Dirichlet":

{

// tag::inlet[]

"inlet":

{

"expr":"{Re/D,0}:Re:D"

}

// end::inlet[]

},

"outlet":

{

// tag::walls[]

"wall1":

{

"expr":"0"

},

"wall2":

{

"expr":"0"

}

// end::walls[]

}

},

"fluid":

{

// tag::outlet[]

"Neumann_scalar":

{

"outlet":

{

"expr":"0"

}

}

// end::outlet[]

}

},

"PostProcess":

{

"Exports":

{

"fields":["velocity"]

}

}

}3. Results

3.1. Running the case:

The command line to run this cases is

mpirun -np 4 feelpp_toolbox_fluid--config-file cylindre.cfg--fluid.snes-monitor=1--fluid.gmsh.hsize=8Once the command is executed the results are exported to ParaView for viewing the flow by executing:

rsync -avz atlas.math.unistra.fr:/feelBibliography

-

[chen-2020] Numerical simulations of flow past three circular cylinders in equilateral-triangular arrangements Chen, Weilin, Ji, Chunning, Alam, Md. Mahbub, Williams, John, Xu, Dong, Journal of Fluid Mechanics2020 / 05 Vol. 891, Download PDF